|

|

Step 1: Glue top/back |

|

|

|

|

Step 2: Cut inlay slot |

|

|

|

|

Step 3: Glue inlay |

|

|

|

|

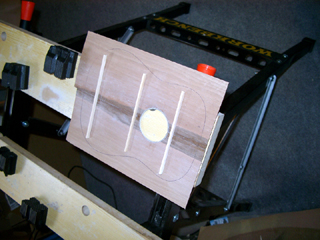

Step 4: Drill sound hole |

|

|

|

|

Step 5: Sound hole binding |

|

|

|

|

Step 6: Draw top shape |

|

|

|

|

Step 7: Top braces |

|

|

|

|

Step 8: Glue braces |

|

|

|

|

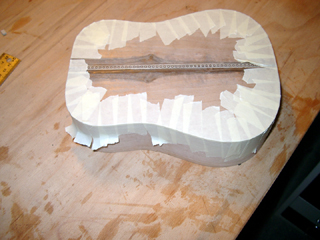

Step 9: Back braces |

|

|

|

|

Step 10: Glue top |

|

|

|

|

Step 11: Glue back |

|

|

|

|

Step 12: Sand top edge |

|

|

|

|

Step 13: Cut top edge |

|

|

|

|

|

|

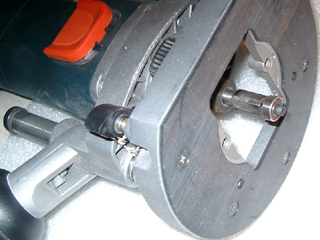

Step 14: Cut binding slot |

|

|

|

|

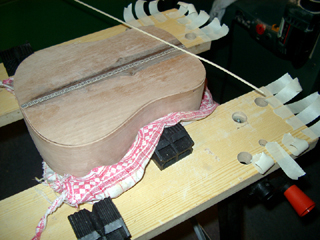

Step 15: Glue and tape binding |

|

|

|

|

Step 16: Cut neck slot |

|

© 2009 powered by

RISA Musical Instruments