|

|

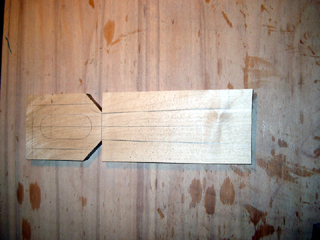

Step 1: Neck shape |

|

|

|

|

Step 2: Cut the neck |

|

|

|

|

Step 3: Pre-drill headstock |

|

|

|

|

Step 4: Drill headstock |

|

|

|

|

Step 5: Sand headstock |

|

|

|

|

Step 6: Glue fingerboard |

|

|

|

|

Step 7: Glue heal |

|

|

|

|

Step 8: Shape neck-heal |

|

|

|

|

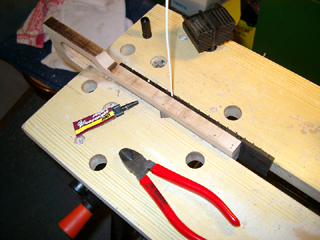

Step 9: Fretting |

|

|

|

|

Step 10: Side dots |

|

|

|

|

Step 11: Glue neck-heal |

|

|

|

|

Step 12: Close fretwire slots |

|

|

|

|

Step 13: Neck shaping |

|

|

|

|

Step 14: Nut slots |

|

|

|

|

Step 15: Glue nut |

|

|

|

|

Step 16: Polish neck |

|

© 2009 powered by

RISA Musical Instruments